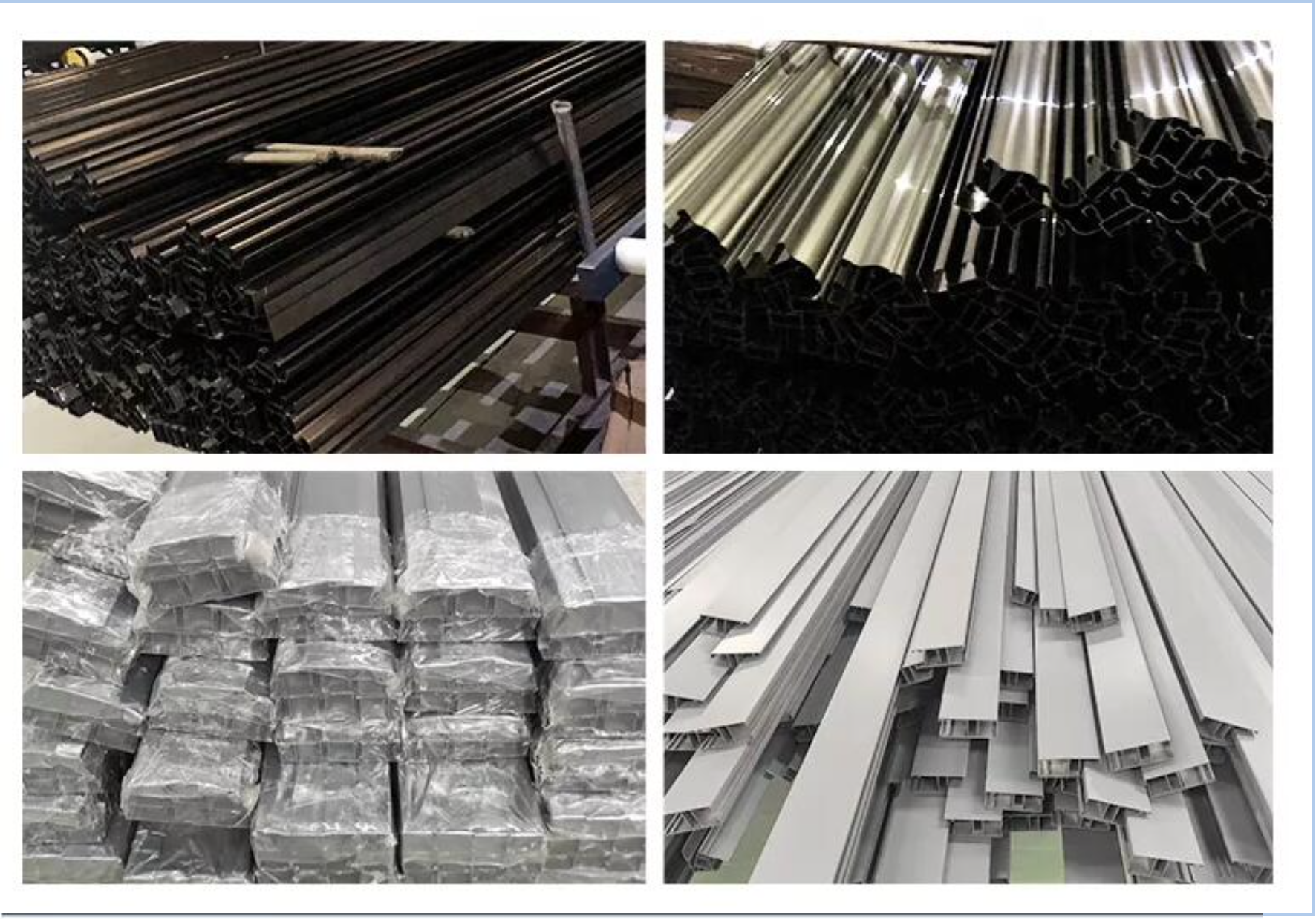

Manufacturing aluminum profiles for doors and windows

Product Overview

Category:

Aluminium Profile

Product Details

Manufacturing aluminum profiles for doors and windows

Aluminum profiles have become increasingly popular in the construction of doors and windows due to their lightweight, durability, and resistance to corrosion. The manufacturing process of these profiles involves several key steps, beginning with the selection of high-quality aluminum alloys that provide optimal strength and flexibility. Once the materials are chosen, they undergo a process known as extrusion, where heated aluminum is forced through a die to create long, continuous shapes that can be cut to specific lengths. This method not only allows for the production of complex cross-sections but also ensures uniformity and precision in the profiles. After extrusion, the profiles are cooled and undergo surface treatments, such as anodizing or powder coating, which enhance their aesthetic appeal and provide additional protection against environmental factors. The final step involves quality control, where each profile is meticulously inspected for defects and tested for structural integrity. With advancements in technology, manufacturers can now produce energy-efficient profiles that meet stringent insulation standards, contributing to the overall energy performance of buildings. This evolution in aluminum profile manufacturing not only meets the growing demand for sustainable construction materials but also aligns with global efforts to reduce energy consumption and carbon footprints in the building industry. As the market for aluminum profiles continues to expand, innovations in design and production techniques will further enhance their application in modern architecture, offering versatile solutions for both residential and commercial projects.

Keywords:

WHY CHOOSE US

Today, we firmly grasp the latest trends in technology development , to provide users with more comprehensive and complete solution in the overall system.

Customized service

Personalized design and manufacturing services for various profiles based on specific customer needs

Quality control and warranty

Strictly screen and evaluate raw material suppliers to assess their production capacity

Customer Service Team

Responsible for handling a series of customer inquiries and after-sales issues

Workshop scale

Has strong production capacity and can produce various profile products on a large scale

Logistics services

Ensure the provision of high-quality, efficient, and reliable logistics services to customers

Cooperative Partner

Select the World's Top Cooperative Brands

Related Products

Focus on minimalist outdoor doors and windows

Welcome to leave a message

Thank you for your message! We will contact you within 24 hours!