language

01

2025

-

10

Exploring the Advantages of Seamless Welding in Aluminium Window Manufacturing

In recent years, the construction and decoration materials industry has seen a surge in demand for high-quality aluminium windows. One of the most significant advancements in this area is the use of seamless welding techniques. Seamless welding of aluminium windows involves a sophisticated process that eliminates the need for traditional mechanical fasteners, providing not only enhanced strength b

In recent years, the construction and decoration materials industry has seen a surge in demand for high-quality aluminium windows. One of the most significant advancements in this area is the use of seamless welding techniques. Seamless welding of aluminium windows involves a sophisticated process that eliminates the need for traditional mechanical fasteners, providing not only enhanced strength but also aesthetic appeal.

**The Process of Seamless Welding**

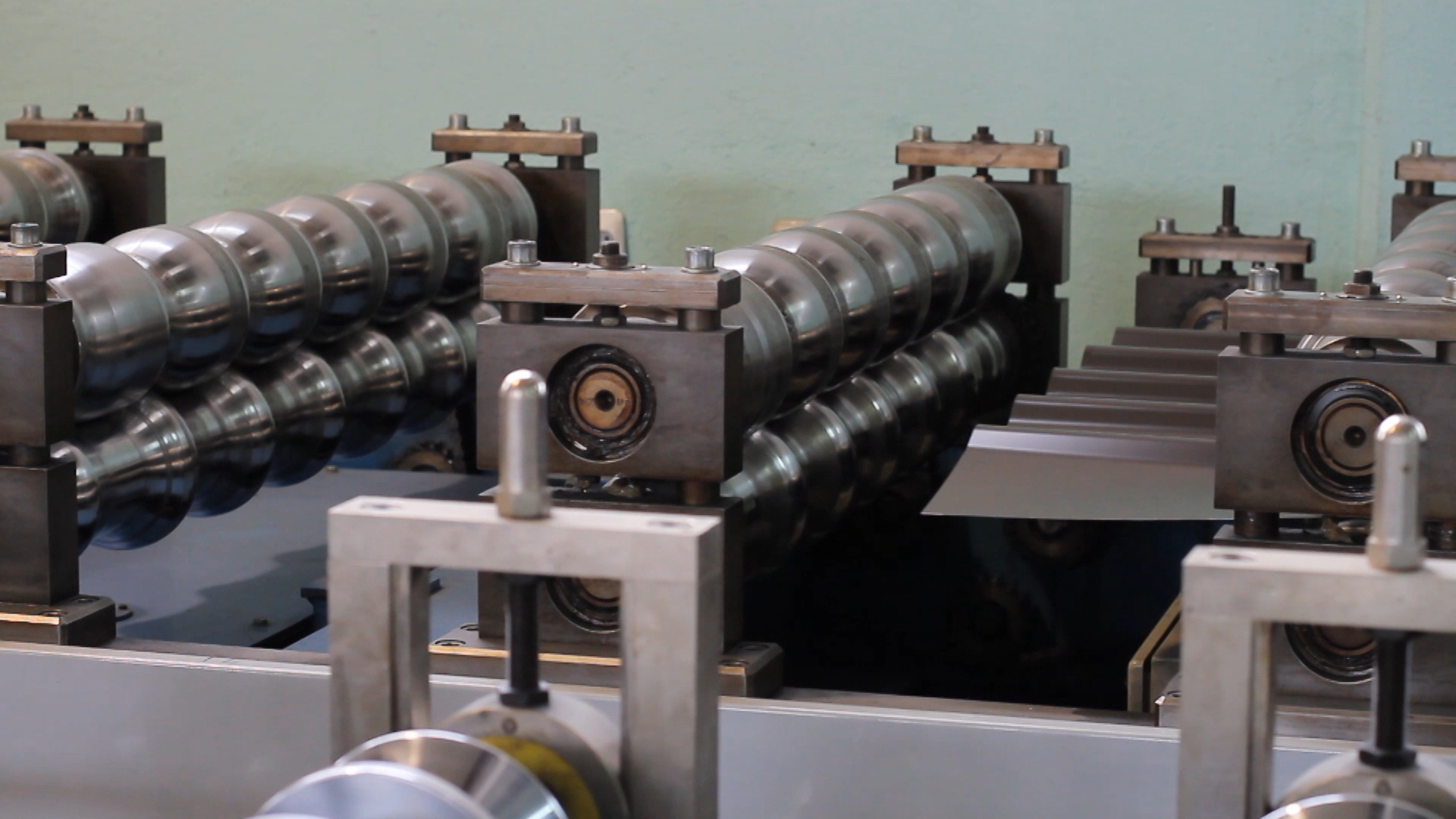

Seamless welding utilizes advanced welding technologies such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding. These methods enable the creation of a continuous bond between aluminium sections without the use of screws or rivets. By employing precise temperature controls and appropriate filler materials, manufacturers can achieve a clean and strong joint that enhances the overall structural integrity of the window frame.

**Benefits of Seamless Welding**

1. **Enhanced Durability**: One of the primary advantages of seamless welding in aluminium windows is the increased durability. The absence of mechanical fasteners reduces potential points of failure, making the windows more resistant to environmental stresses such as wind, rain, and temperature fluctuations. This ensures a longer lifespan for the windows, benefiting both builders and homeowners.

2. **Improved Aesthetics**: Seamless welding offers a sleek and modern appearance. With no visible fasteners, the finished product has a clean and sophisticated look, appealing to contemporary design preferences. This visual appeal is particularly important in high-end residential and commercial projects, where aesthetics play a crucial role in the overall architectural vision.

3. **Energy Efficiency**: The seamless joints created during the welding process contribute to better thermal performance. Traditional window frames often have gaps and seams that can lead to air leakage, ultimately affecting energy efficiency. Seamless welded aluminium windows, on the other hand, provide a tighter seal, reducing energy loss and enhancing thermal insulation, which is essential for maintaining comfortable indoor temperatures.

4. **Ease of Maintenance**: Seamless welded aluminium windows are generally easier to maintain compared to those with mechanical fasteners. The streamlined design minimizes the accumulation of dirt and debris in joints, making cleaning simpler and more efficient. This feature appeals to both homeowners and property managers seeking low-maintenance solutions.

**Conclusion**

In conclusion, seamless welding of aluminium windows represents a significant innovation in the building and decoration materials sector. By offering enhanced durability, improved aesthetics, increased energy efficiency, and ease of maintenance, this method addresses various needs of modern architecture. As the industry continues to evolve, embracing such advanced techniques will undoubtedly play a pivotal role in creating more sustainable and visually appealing structures.

**The Process of Seamless Welding**

Seamless welding utilizes advanced welding technologies such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding. These methods enable the creation of a continuous bond between aluminium sections without the use of screws or rivets. By employing precise temperature controls and appropriate filler materials, manufacturers can achieve a clean and strong joint that enhances the overall structural integrity of the window frame.

**Benefits of Seamless Welding**

1. **Enhanced Durability**: One of the primary advantages of seamless welding in aluminium windows is the increased durability. The absence of mechanical fasteners reduces potential points of failure, making the windows more resistant to environmental stresses such as wind, rain, and temperature fluctuations. This ensures a longer lifespan for the windows, benefiting both builders and homeowners.

2. **Improved Aesthetics**: Seamless welding offers a sleek and modern appearance. With no visible fasteners, the finished product has a clean and sophisticated look, appealing to contemporary design preferences. This visual appeal is particularly important in high-end residential and commercial projects, where aesthetics play a crucial role in the overall architectural vision.

3. **Energy Efficiency**: The seamless joints created during the welding process contribute to better thermal performance. Traditional window frames often have gaps and seams that can lead to air leakage, ultimately affecting energy efficiency. Seamless welded aluminium windows, on the other hand, provide a tighter seal, reducing energy loss and enhancing thermal insulation, which is essential for maintaining comfortable indoor temperatures.

4. **Ease of Maintenance**: Seamless welded aluminium windows are generally easier to maintain compared to those with mechanical fasteners. The streamlined design minimizes the accumulation of dirt and debris in joints, making cleaning simpler and more efficient. This feature appeals to both homeowners and property managers seeking low-maintenance solutions.

**Conclusion**

In conclusion, seamless welding of aluminium windows represents a significant innovation in the building and decoration materials sector. By offering enhanced durability, improved aesthetics, increased energy efficiency, and ease of maintenance, this method addresses various needs of modern architecture. As the industry continues to evolve, embracing such advanced techniques will undoubtedly play a pivotal role in creating more sustainable and visually appealing structures.

seamless welding aluminium window