language

11

2025

-

10

How Seamless Welding Enhances the Durability of Aluminium Windows

How Seamless Welding Enhances the Durability of Aluminium Windows Table of Contents 1. Introduction to Aluminium Windows 2. What is Seamless Welding Technology? 3. Benefits of Seamless Welding in Aluminium Windows 4. How Seamless Welding Enhances Durability 5. The Role of Seamless Welding in Energy Efficiency 6. Aesthetic Benefits of Seamless Aluminium Windows 7. Applications of Sea

How Seamless Welding Enhances the Durability of Aluminium Windows

Table of Contents

- 1. Introduction to Aluminium Windows

- 2. What is Seamless Welding Technology?

- 3. Benefits of Seamless Welding in Aluminium Windows

- 4. How Seamless Welding Enhances Durability

- 5. The Role of Seamless Welding in Energy Efficiency

- 6. Aesthetic Benefits of Seamless Aluminium Windows

- 7. Applications of Seamless Aluminium Windows

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Aluminium Windows

Aluminium windows have steadily gained popularity in both residential and commercial buildings due to their strength, lightweight nature, and versatility. The increasing demand for energy-efficient and aesthetically pleasing structures has led to the advancement of construction techniques, particularly in the manufacturing of window frames. Among these techniques, **seamless welding** stands out as a transformative process that significantly enhances the durability and performance of aluminium windows.

2. What is Seamless Welding Technology?

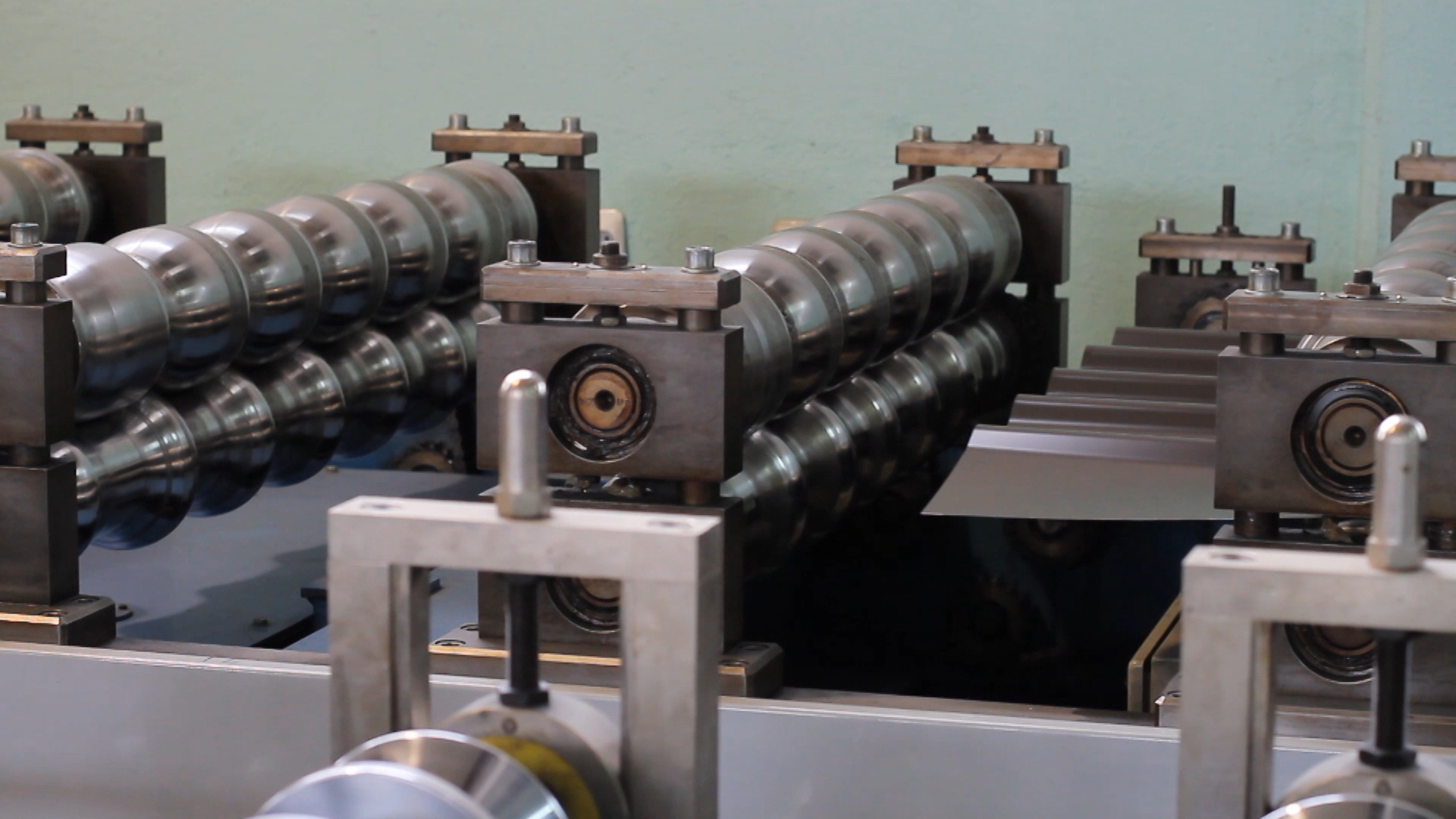

Seamless welding is a cutting-edge manufacturing process that involves joining aluminium pieces without the use of traditional mechanical fasteners such as screws or rivets. Instead, this method employs advanced welding techniques, which create a continuous bond between the materials. This results in a strong, uniform structure that is not only visually appealing but also offers superior performance compared to conventional methods.

2.1 Types of Seamless Welding Techniques

There are several types of welding techniques used in seamless welding, including:

- **TIG (Tungsten Inert Gas) Welding:** This method uses a non-consumable tungsten electrode to produce the weld. It is known for its precision and is ideal for thin materials.

- **MIG (Metal Inert Gas) Welding:** MIG welding employs a continuously fed wire and is suitable for various thicknesses, making it versatile for different aluminium window applications.

- **Laser Welding:** This high-precision technique uses a laser beam to join materials. It offers minimal heat input, reducing the risk of warping and ensuring a clean finish.

3. Benefits of Seamless Welding in Aluminium Windows

Seamless welding offers numerous advantages over traditional joining methods, particularly in the context of aluminium windows. These benefits include:

- **Increased Strength:** The continuous weld creates a robust bond, enhancing the overall strength of the window frame.

- **Improved Weather Resistance:** Seamless joints minimize water ingress and air leaks, leading to better performance in various weather conditions.

- **Reduced Maintenance Requirements:** The durability of seamless welding reduces the need for frequent repairs and maintenance, ultimately saving time and costs.

- **Enhanced Thermal Performance:** Seamless welded windows tend to have better insulation properties, contributing to energy efficiency.

4. How Seamless Welding Enhances Durability

Durability is a critical factor in the performance of aluminium windows, and seamless welding plays a vital role in enhancing this quality. Several mechanisms contribute to this enhanced durability:

4.1 Resistance to Corrosion

Aluminium is naturally resistant to corrosion due to the formation of a protective oxide layer. However, the use of mechanical fasteners can compromise this layer, leading to potential corrosion sites. Seamless welding eliminates these weak points, ensuring a uniform layer of protection across the entire frame.

4.2 Structural Integrity

The seamless bond created through welding provides superior structural integrity compared to traditional methods. This means that windows can withstand greater forces from wind and impact, making them ideal for various environments, particularly in coastal or storm-prone areas.

4.3 Longevity

Seamless welded windows are built to last. Their enhanced strength and resistance to environmental factors mean they can maintain their functionality and appearance for decades, making them a worthwhile investment for homeowners and builders alike.

5. The Role of Seamless Welding in Energy Efficiency

In today's environmentally conscious world, energy efficiency is a top priority for many homeowners and builders. Seamless welding contributes significantly to energy savings in aluminium windows in several ways:

5.1 Improved Insulation

The continuous joints created by seamless welding reduce thermal bridging, which occurs when heat escapes through the frame. This improved insulation helps maintain comfortable indoor temperatures, reducing the reliance on heating and cooling systems.

5.2 Lower Energy Bills

By enhancing insulation properties, seamless welded windows can help homeowners save on energy bills. The reduced energy consumption not only benefits the environment but also contributes to lower operating costs for buildings.

6. Aesthetic Benefits of Seamless Aluminium Windows

Beyond functionality, seamless welding enhances the aesthetic appeal of aluminium windows, making them a popular choice in contemporary architecture.

6.1 Sleek and Modern Appearance

Seamlessly welded windows offer a sleek, minimalist look that is highly sought after in modern designs. Without visible fasteners or joints, these windows provide a clean, uninterrupted surface that enhances the overall aesthetic of any structure.

6.2 Versatile Design Options

The flexibility of seamless welding allows for innovative designs that can be tailored to meet specific architectural requirements. This versatility enables architects and builders to create unique and visually striking window solutions.

7. Applications of Seamless Aluminium Windows

Seamless aluminium windows are suitable for a wide range of applications, including:

- **Residential Buildings:** Homeowners are increasingly opting for seamless welded windows to enhance energy efficiency and aesthetic appeal in their homes.

- **Commercial Properties:** Businesses benefit from the durability and low maintenance of seamless windows, making them a practical choice for office buildings and retail spaces.

- **High-Rise Structures:** The strength of seamless welded frames makes them ideal for high-rise buildings, where windows must withstand greater external forces.

8. Conclusion

Seamless welding has revolutionized the construction of aluminium windows, offering unparalleled durability, energy efficiency, and aesthetic appeal. By eliminating weak points typically associated with traditional fastening methods, seamless welded windows provide a robust and long-lasting solution for both residential and commercial applications. As the demand for high-performance building materials continues to grow, the advantages of seamless welding make aluminium windows an outstanding choice for modern architecture.

9. Frequently Asked Questions

1. What is the main advantage of seamless welding in aluminium windows?

The primary advantage of seamless welding is the creation of a continuous bond that enhances strength, durability, and resistance to environmental factors.

2. How does seamless welding affect energy efficiency?

Seamless welding improves insulation by reducing thermal bridging, leading to lower energy consumption and reduced utility bills.

3. Are seamless welded windows more expensive than traditional windows?

While the initial cost may be higher, the long-term savings on maintenance and energy costs often make seamless welded windows a more economical choice.

4. Can seamless welding be used for other materials besides aluminium?

Yes, seamless welding techniques can be applied to various materials, although aluminium is one of the most common due to its favorable properties.

5. How can I tell if my aluminium windows are seamless welded?

Inspect the edges of the frame; seamless welded windows will have smooth, uninterrupted joints without visible fasteners or rivets.

seamless welding aluminium window